Our ‘state of the art facility’ took the environment into account at every stage of development and will continue to as we grow; so it seemed natural to aim for ISO 14001 – a worldwide standard for environmental improvement for businesses.

ISO 14001 helps the company to be more environmentally friendly, whether it’s how we get rid of our waste to how we reuse our packaging or even what times we use the most electricity; we manage this through our aspects and impacts register.

Waste management policy for staff in the production department.

Our environmental impacts are how our activities as a business affect the environment, from emissions to natural resource usage through to how much of our waste goes to landfill. We look at our highest impacts and come up with objectives to try and cut these impacts down.

Our main areas of focus for the coming year are Electricity, Gas & Waste.

Towards Solar

Solar PV has been a focus of the company for quite some time now. As an electricity thirsty company, creating our own energy and being self-sufficient is a real plus. The benefits of Solar PV are numerous, cutting down natural resource usage, protecting ourselves against grid failures and protecting the environment are key drivers for us.

Recycling Waste Heat

Our internal processes create a lot of residual heat, from our BOGE compressors to our hot-flow ovens we lose a lot of heat to the atmosphere. A heat exchanger is a way to capture this heat and use it to reheat our production areas and cut down on gas usage. We’re exploring the options as we speak and are hoping to implement this as soon as possible.

Re-use, Recycle & Sort

This idea is circulated around our colleagues and work environment on a daily basis. Saving the environment is mostly about changing our mindset and this methodology is something we try to promote on a daily basis.

So if we can reuse we will, if we can recycle we will and if all else fails we sort the waste in a responsible way.

Our waste streams include general waste, mixed recycling and hazardous waste. Reuse starts with packaging which comes into the company, this is mostly cardboard which we then reuse for goods which we dispatch to our customers. We currently reuse about 75% of the cardboard packaging which comes in and we are aiming for a 100% in the future.

If packaging types can’t be reused we look to recycle, our waste management scheme is aimed to be simple to manage, recyclable items are put into mixed recycling which is often referred to as commingled waste. This includes paper, plastic and cardboard which is then sorted by our waste contractor at a special recycling plant. We planned to encourage recycling through ‘ease of access’ the idea being if it’s easy to do, the more invested people become. A good example of this is staff washing yogurt pots so they can be put into mixed recycling rather than into ‘general waste’ which is something which we see on a daily basis.

Finally if it can’t be recycled it goes to general or hazardous waste. General waste tends to be food waste or contaminated waste, essentially if it has food on it, it’s contaminated.

For us hazardous waste is minimal, it comes in the form of waste solder (solder dross) from our surface mount technology or as electrical waste like batteries or populated PCB’s. We have an ‘Ecobox’, a single location for all for our hazardous waste again to simplify how we manage our waste.

Monitoring gas and water usage.

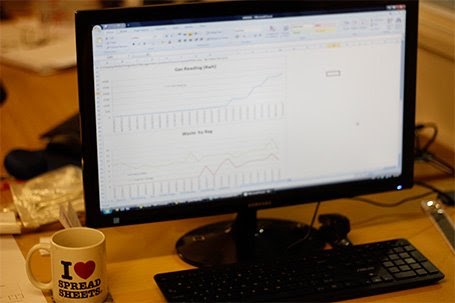

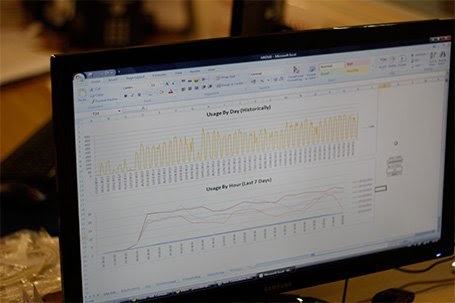

Monitoring electricity usage.

End.